| Available Products |

| Letre 900 and 800 Filters These large volume plate and frame filter presses are designed with internal feed and discharge porting. No gasketing is required and they can be used with a wide variety of filter media including media with different thickness specifications. The Letre 900 and 800 filters are supplied with pneumatic/hydraulic closures standard to provide simple joystick operation. An automatic pressure setting maintains balanced pressure on the filter media throughout the entire production run. These units can accommodate up to 120 filter pads, providing a filtration area up to 86.4 m2. Selection of inlet frame thickness will determine the volume of cake that can be accumulated and washed for product recovery. |

The Letre 600 & 604 filters are the industry standard for filtration of critical liquids. Letre 604 filters are fitted with four ports which can be configured for thorough washing. As with other internally ported filter assemblies, gaskets and washers are not required. In applications where sanitary designs are required, Letre 600 & 604 can be provided with BioClean™ filter plates.

The EUS filter is designed for mid-range batch sizes. It can accept up to one hundred 16 in. sq. pads providing up to 13.2 m2 of installed filter area. The EUS filter is equipped with BioClean™ filter plates as standard. This eliminates all screw and internal threads, which reduces cleaning and sterilization time.

2HS and 2HS-B Filters

These economical 30 cm diameter plate and frame filter presses are designed for a wide range of high efficiency, ultra fine filtration applications. They accept up to 40 filter pads and provide up to 2.3 m2 of installed filter area.Model 2HS is cart mounted and is available with a 40 pad capacity expansion option. Model 2HS-B is mounted on a floor level dolly and has a filter pad capacity of up to 12 pads.Model 2HS and 2HS-B filters have the same component flexibility as other ErtelAlsop plate and frame filter presses. This includes sludge inlet rings for cake accumulation, dividing heads for multiple-step/one-pass filtration, sanitary fittings, special piping, gauges, pumps, and motors to meet a wide range of applications.

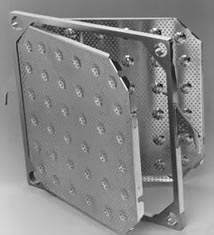

BioClean™ Filter Plates

Designed to meet rigid cleaning validation standards, optional BioClean plates are ideal for all sanitary and ultra-clean depth filter applications. BioClean™ filter plates are an integral element in the ideal upstream filtration sequence that leads to successful downstream processing - up to and including sterile filtration of the finished product. The BioClean™ filter plate assembly consists of a frame and two screen sections. The screens are designed with a series of protrusions, or dimples, on opposing screens which make contact when the filter press is closed.This action maintains the position of the plates without the need for welds or mechanical interconnections, and prevents the plates from bowing inward while under pressure during filtration. Cleaning and sterilization is fast and simple.Our patented innovation is the only design that allows for ultra-high polishing of all liquid contact surfaces.